least count of rockwell hardness tester|rockwell hardness tester chart : exporting In regular Rockwell testing the minor load is always 10 kgf (kilograms of force). The major load can be any of the following loads: 60 kgf, 100 kgf or 150 kgf. No Rockwell hardness value is . WEBAt Mr Bet online Canadian casino, we are a legit and licensed crypto casino that welcomes players across the country. We offer a safe and secure desktop & mobile-optimized .

{plog:ftitle_list}

webComentários. Veja todas as críticas de "Pantera Negra: Wakanda Para Sempre" da redação do AdoroCinema : Quando Chadwick Boseman faleceu em agosto de 2020, deixou um buraco no coração de seus .

Description. The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale (HRC 20-70). Soft materials are tested using a 1/16" carbide ball indenter in the B-scale (HRB .

Rockwell Hardness Testing Machine HR-530 Series Unique electronic control makes the HR-530 series of hardness testers capable of Rockwell, Rockwell Superficial, Rockwell testing of .• VERTEX make Rockwell hardness testers are suitable for checking hardness of metals and their alloys. • Flat, Round as well as irregular types for components considering can be tested .In regular Rockwell testing the minor load is always 10 kgf (kilograms of force). The major load can be any of the following loads: 60 kgf, 100 kgf or 150 kgf. No Rockwell hardness value is .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

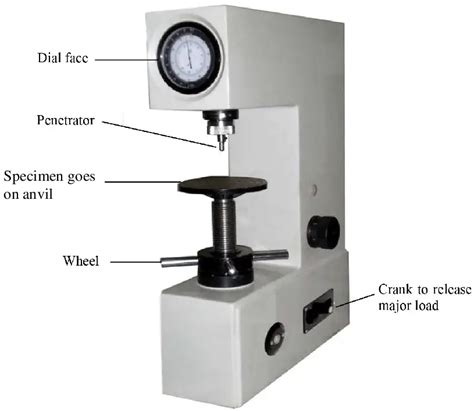

A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a .The Rockwell test measures the permanent depth of indentation produced by a specified force/load on a specified indenter. The Rockwell test requires the least amount of sample prep .

rockwell hardness testing standards

The Rockwell Hardness Test is actually one of several tests aimed to gauge a material’s compatibility as a component to an object based on their strength and durability. The other tests in the series include the the .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared .ROCKWELL HARDNESS TEST 1. AIM: To determine the Rockwell Hardness of a given test specimen II. APPARATUS: Rockwell Hardness testing machine, Test specimen. III. THEORY: . Least count of Brinell Microscope = HB = 2 ( 2 2) 2 mm kg D D D d F S Sl.No. Impression Diameter F in kG T in sec D in mm HB d Kg/mm 2 1 d2 2 d1 d 2

profiles. The Rockwell test is the most popular indentation hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds,Find here Digital Rockwell Hardness Testing Machine, Digital Rockwell Hardness Tester manufacturers, suppliers & exporters in India. . Least Count 0.1 HRC ₹ 1,20,000 Get Latest Price. Parameter. HRC. Display Type. Digital. Model Name/Number. TRH-150D. Accuracy. LEAST COUNT 0.1 HRC. Automation Grade. Automatic. Hardness Scale. HRA, HRB, HRC .The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .The minimum Test Specimen thickness is at least 10 times the indentation depth as per ASTM standard and the same is at least 8 times the indentation depth as per ISO standard. 5. Unit of Brinell Hardness . For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC)

The ASTM specifies thirty different Rockwell scales, each employing a different combination of test forces and indenter types, which allows the testing Test Procedure of most types of metallic materials and products. When Rockwell hardness is called out by a product standard or specification, the choice of scale is usually specified. In situations where the user must choose .Manufacturer of Hardness Tester - Digital Portable Hardness Tester, Optical Vickers Hardness Tester offered by Nova Engineers And Instruments, Mumbai, Maharashtra. . Brinell Cum Rockwell Hardness Tester Calibration Service; . Scale Least count: 0.001MM: Depth of Throat: 135MM: Optical Magnifications: 70X: Dimensions: 540mmx280mmx850mm (L x .

The material being tested must have a thickness that is at least ten times greater than what the Rockwell indentation will be when manufactured of the material is. . The Rockwell hardness test is an indentation hardness test that involves .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, . Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, .The ZwickRoell Indentec Rockwell hardness testers with dead weights and frictionless load application. Available in different configurations for both classic Rockwell and superficial Rockwell hardness testing. The innovative nose mounting feature of the indenter provides unsurpassed accessibility for hard to reach measuring points. Inner surfaces of parts can be .

main test force loading/unloading, high resolution digital display and USB data storage. The 3831 is suitable for testing hardness of carbon steel, alloy steel, cast iron, non ferrous metals and engineering plastics. The tester meets the following standard: ASTM E18, ISO 6508-2, and BS EN ISO6508-2. 2 Key performance parameters

Our expert help has broken down your problem into an easy-to-learn solution you can count on. . In Rockwell hardness test, an initial minor load is applied, followed by a major load. Specimen thickness should be at least 10 times the depth of the indentation. QUESTION 15 Tensile stress is defined as the tensile force per unit cross section area.Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

Digital Rockwell Hardness Tester, Model Name/number: Atedigihr,. ₹ 48,200 Get Quote Digital Pu Foam Indentation Hardness Tester, Model Name/number:. ₹ 1,74,500Manufacturer of Rockwell Hardness Testers - Load Cell Based Touch Screen Rockwell Hardness Tester, Load Cell Based Touch Screen Rockwell Cum Superficial Hardness Tester, Motorized Digital Rockwell Hardness Tester and Analogue Rockwell Hardness Tester offered by Om Engineering Instruments, New Delhi, Delhi.

Motorized Digital Rockwell Hardness Tester; Touch Screen panel for Dwell time selection and test cycle start. Automatic testing (Loading, Dwell, Unloading) after applying the preliminary test force by hand. . Least Count: 0.1 HR: Data Output: Mini USB Port: Memory: 500 Readings: Max. test height: 180mm: Depth of throat: 135 mm (from the .

Rockwell hardness tester: quick & easy. The Rockwell hardness tester uses the method as defined in ISO 6508 & ASTM E18, which is the most commonly used method around the world to determine a material’s hardness.. This test is suitable for almost all metals and to some degree for plastics. The Rockwell test measures the permanent depth of indentation produced by a .

Rockwell Hardness Tester Model No. 3814 Operation Manual . TECHNICAL SUPPORT: (201) 9962-8352 . Hardness Tester must be installed in a dust and vibration free environment. Mount tester to a support bench or table for a load of at least 500 lbs. 1. Position tester on support surface as desired, mark location of the 4 mounting holes in the .Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the world’s leading materialographic and metallographic experts. . Sample thickness ASTM: At least 10 times .

rockwell hardness tester manual

webNossa História. Nós somos os integrantes mais novos de uma família que já existe há mais de 80 anos. E, mesmo que a gente pudesse escolher alguma outra, não mudaríamos. Temos muito orgulho de fazer parte da história da Zanlorenzi que sempre atuou no ramo de bebidas, fabricando vinhos de mesa, espumantes e, há alguns anos, sucos e chás.

least count of rockwell hardness tester|rockwell hardness tester chart